By using innovative imaging techniques, researchers have shown that crack complexity increases material toughness, challenging traditional views and suggesting new approaches in material design and testing. Credit: SciTechDaily.com

By capturing a rare glimpse into three-dimensional crack formation in brittle solids, EPFL researchers have found that complex cracks require more energy to advance than simple ones; a discovery that could improve materials testing and development.

The last time you dropped a favorite mug or sat on your glasses, you may have been too preoccupied to take much notice of the intricate pattern of cracks that appeared in the broken object. But capturing the formation of such patterns is the specialty of John Kolinski and his team at the Laboratory of Engineering Mechanics of Soft Interfaces (EMSI) in EPFL’s School of Engineering. They aim to understand how cracks propagate in brittle solids, which is essential for developing and testing safe and cost-effective composite materials for use in construction, sports, and aerospace engineering.

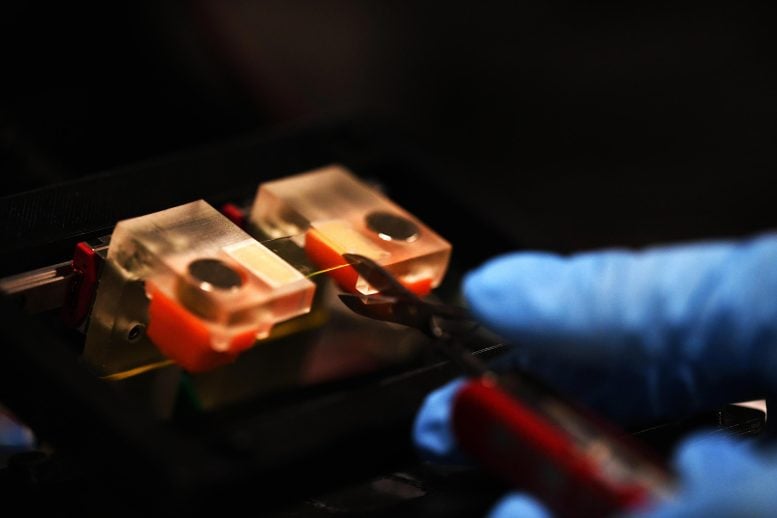

The scientists induced cracks in hydrogel samples with a standard Swiss Army knife. Credit: EMSI EPFL CC BY SA

Understanding 3D Crack Complexity

But traditional mechanics approaches to analyzing crack formation assume that cracks are planar – i.e., that they form on the two-dimensional surface of a material. In fact, simple planar cracks are just the tip of the iceberg: most cracks – like those in everyday brittle solids like glass – propagate into three-dimensional networks of ridges and other complex features.

Due to material opacity and the speed with which cracks form, observing this complexity in real time is extremely difficult. But now, armed with a Swiss Army knife and a confocal microscope, Kolinski and his team have managed to do just that – and they have discovered a positive correlation between crack complexity and material toughness in the process.

“The energy required to drive cracks has traditionally been considered a material property, but our work yields unique insights into the key role of geometry: namely, that by increasing the complexity of geometric features at the crack tip, a material can be made effectively tougher, because more strain energy is required to advance a complex crack than a simple one,” Kolinski says. “This highlights an important gap in the current theory for 3D cracks.”

The lab’s results have recently been published in Nature Physics.

A Fundamental Link Between Length and Strength

The researchers’ method involved creating very thin slices of four different hydrogels and an elastomer. Transparent and brittle, but easy to deform and measure without shattering, the hydrogels served as a proxy for understanding how cracks form in glass and brittle plastics. The elastomer was likewise a proxy for materials like rubber and silicone polymers.

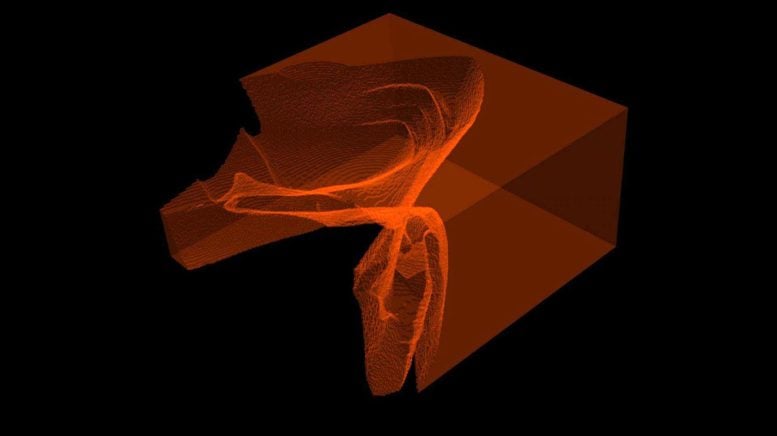

While the experimental cracks were observed with a state-of-the-art confocal microscope, they were induced using a standard Swiss Army knife: the shearing action of the device’s scissors naturally produced geometrically complex cracks in the hydrogel samples. Using a custom apparatus developed by the EMSI team to control sample alignment and loading, a series of fluorescent images was generated with the confocal microscope, and then stacked to assemble a unique, three-dimensional map of each fracture surface.

“People have long known that cracks can become complex by looking at fracture surfaces after the fact, but what is lost is the understanding of the loading conditions when the crack emerged, or what forces the sample was exposed to,” Kolinski explains. “Our innovative imaging method has made it possible to characterize this relationship rigorously in-situ.”

A rendering of 3D crack front data in a brittle hydrogel recorded with a confocal fluorescence microscope. Credit: EMSI EPFL CC BY SA

Experimental Insights and Implications

In a nutshell, these experiments revealed that the strain energy required to drive the sample cracks was directly proportional to the lengths of the crack tips. This suggests that the increased geometric complexity of a 3D crack generates more fracture surface as the crack advances, thus requiring additional strain energy to drive it.

In another experiment, the researchers showed how, as a smoother crack approached a rigid obstacle embedded in the sample, the crack’s planar symmetry was broken, increasing both the crack tip length and the energy required to drive the crack forward.

“The fact that we can isolate how geometric complexity emerges with such an inhomogeneity in the material could motivate new design approaches,” Kolinski says. “Our work also highlights the importance of care in carrying out materials testing, as we now know that any geometric deviation from a planar crack front may lead to a mis-measurement – and potentially dangerous over-estimation – of material toughness.”

Reference: “Complexity of crack front geometry enhances toughness of brittle solids” by Xinyue Wei, Chenzhuo Li, Cían McCarthy and John M. Kolinski, 22 March 2024, Nature Physics.

DOI: 10.1038/s41567-024-02435-x